1. Woodwork Tool Information:

(1) Endmill Type: 5A Double-End One-Flute CNC Cutting Tool

(2) Production Material: High-Quality Solid Tungsten Steel

(3) Spiral Bit Applications:

-

Commonly used for solid wood cutting,

-

contour trimming and cutting of MDF, multi-layer boards, plywood, antique-style furniture, solid wood beds, craftwork, etc.

(4) Applicable Machines:

-

Carving machinery, precision engraving machines, CNC machine tools.

2. Milling Cutter Features:

-

Preminum tungsten carbide material, industry-grade.

(2) Sharp Cutting-Edge:

-

Mirror-finished edge, sturdy blade body, high toughness & durability, long service life.

(3) Large-Capacity Chip Flute:

-

Enables rapid cutting and efficient chip ejection,

-

Even smooth and refined cut surface, The finish is clean, resists chip-adhesion.

(4) Sharp & Mark-Free:

-

Resists chipping during cutting, minimizes surface damage to wood workpiece,

-

and leaves edges burr-free.

(5) Wide Applications:

-

Excels in vertical cutting, contour trimming, and profile cutting.

-

Features high resistance to breakage and wear, effectively improves operational efficiency.

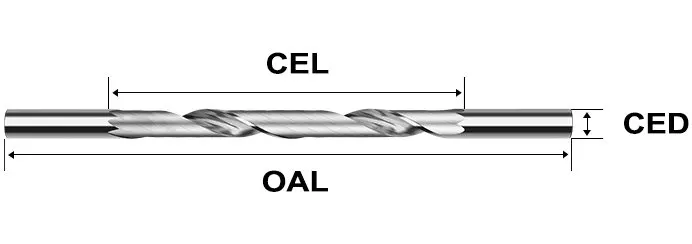

3. Trimming Router Bit Specifications:

Warm Notice:

-

Custom orders are welcome. Contact us for specifications not listed.

4. CNC Tool User Guide:

-

(1) Prior to operation, check the tool for runout.

-

Do not commence cutting if the tool runout exceeds 0.01 mm; correct it first.

-

-

(2) The shorter the length of the cutter protruding from the collet, the better.

-

If the tool overhang is relatively long, it is necessary to reduce the spindle speed, feed rate, or depth of cut.

-

-

(3) During the cutting process, if abnormal vibration or noise occurs,

-

please reduce the spindle speed and depth of cut until the condition improves.

-

-

(4) Spray or air-jet method is recommended for steel cooling, as it enhances the performance of milling cutters.