65HRC Three-Tooth Threading Endmill Cutter

CNC Milling Tool for Aluminum Steel Metal Cutting

1. Thread Cutter Information:

-

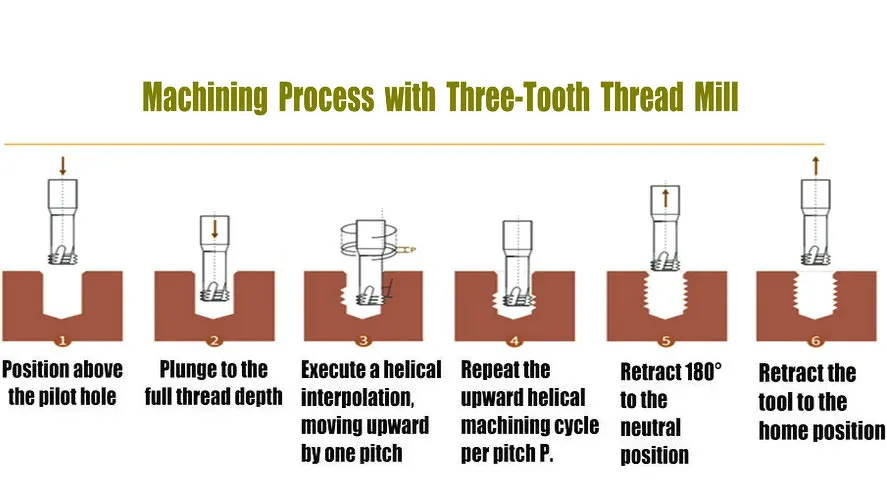

Endmill Name: Thread Milling Cutter Tool.

-

Type: Three-Tooth Thread End Mills;

-

Materials: New Ultra-Fine Grain Tungsten Steel;

-

Thread Standard: Metric;

-

Pitch Type: Coarse / Fine;

-

Flute Numbers: 3/4 Flute;

-

HRC: 65°.

-

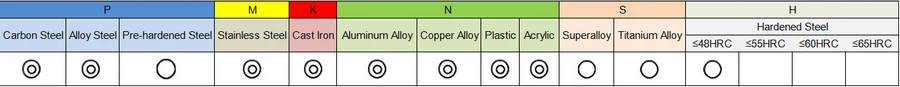

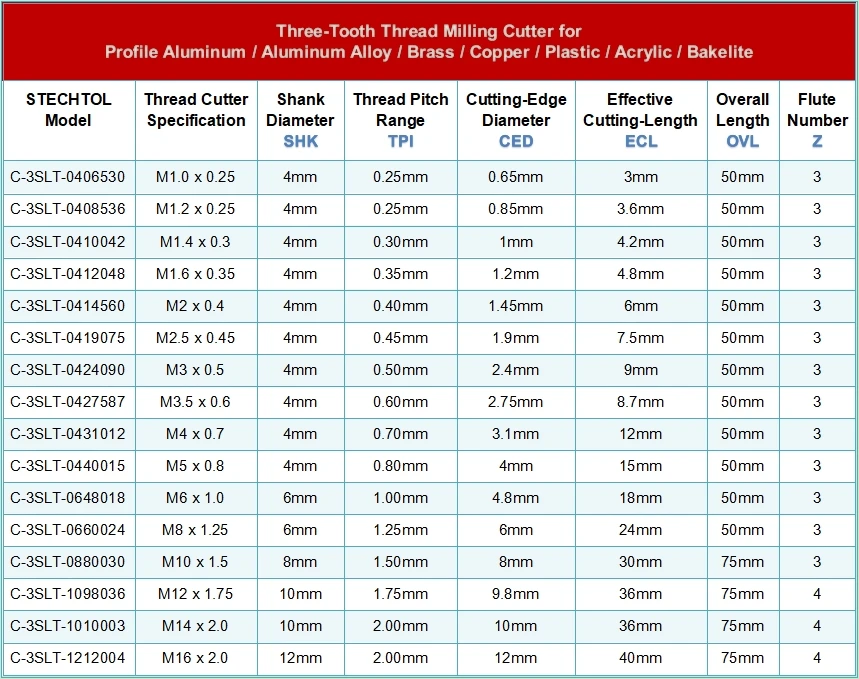

Uncoated Cutter Machining:

-

Profile aluminum, aluminum alloy, brass, copper, plastic, acrylic, bakelite.

-

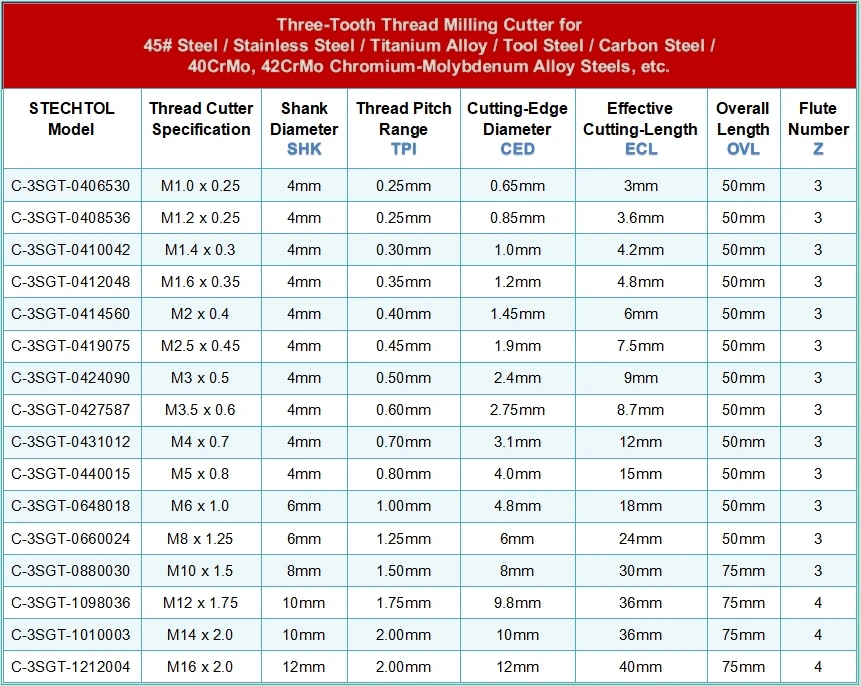

Coated Cutter Machining:

-

45# steel, stainless steel, titanium alloy, tool steel, carbon steel,

-

40CrMo, 42CrMo, chromium-molybdenum alloy steels, etc.

-

Applied Equipment:

-

CNC machining center, precision cnc engraver, and other machinery.

2. Router Bit Features:

-

Ultra-Fine Grain Rod Materials:

-

Selected tungsten steel, using brand-new ultra-fine particle rod as the tool matrix,

-

Not only has high rigidity and excellent wear-resistance, but also can withstand pressure and explosion,

-

Providing strong guarantee for its service life.

-

Nano-Coated:

-

Processed using high-density and wear-resistant coating technology, with better durability & higher strength,

-

Greatly improving the service life of cutting bits.

-

Large Chip-Removal Groove Design:

-

Fully ground spiral angle. The large chip removal space is not prone to chip accumulation,

-

Smooth chip-removal, no burrs, good cutting efficiency.

-

Smooth Cutting:

-

Multiple rows of large spiral chip grooves can easily remove chips,

-

Effectively avoiding tool sticking, improving work efficiency.

-

The processed threads are precise with high smoothness.

-

High Quality:

-

Finely grinding helix angles, large core diameter design, enhanced rigidity and resistance,

-

Sharp and durable, with an extended lifespan.

-

Key Advantages of Tri-ToothThread Mill:

-

High cost-effectiveness. Faster than single-tooth.

-

A leading tooth is milled, followed by the subsequent two teeth finishing, but non-adjustable, with fixed pitch machining.

-

Designed with chip clearance.

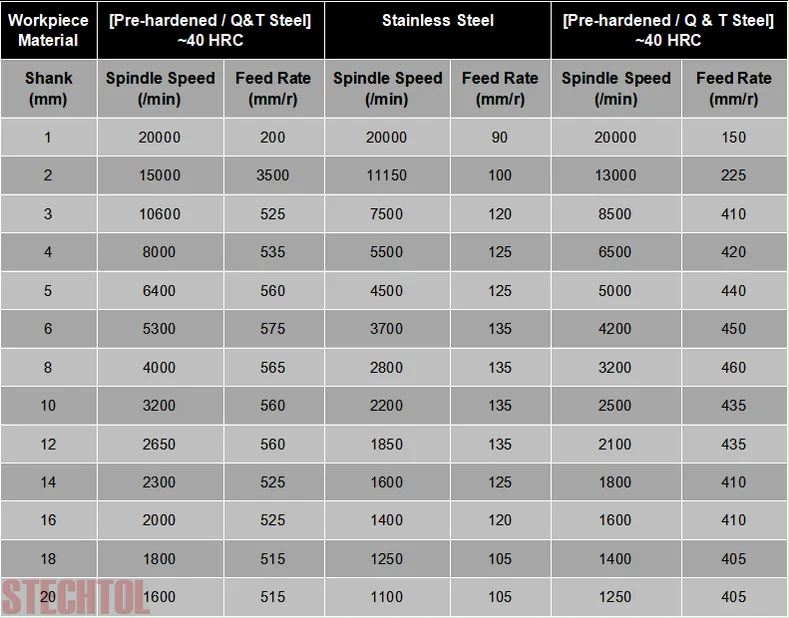

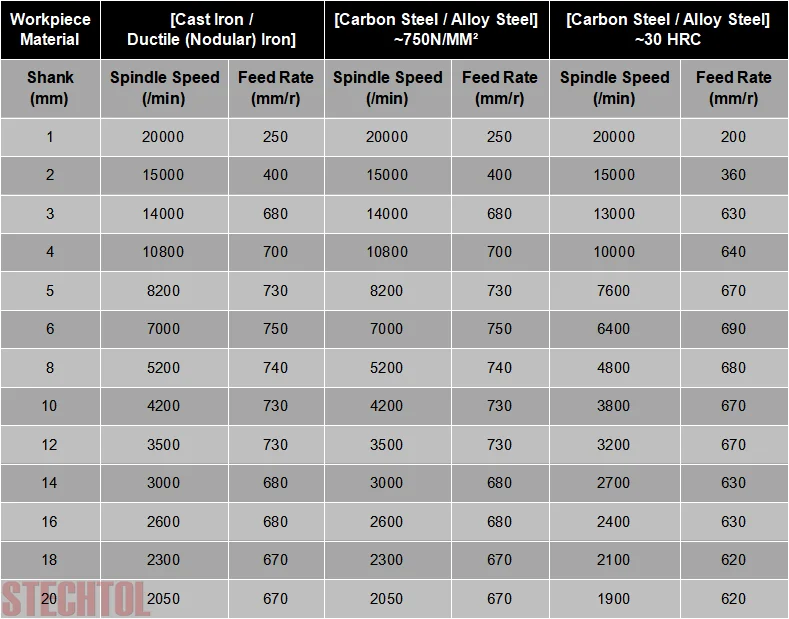

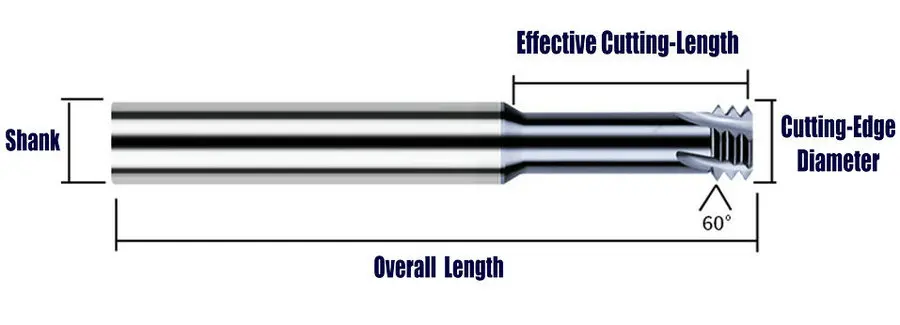

3. Helical Mill Cutter Specifications:

4. CNC Tool Parameter Setting