65 HRC 4 Flute Single-Tooth Thread Milling Cutter

for Steel Aluminum Metal Threading

1. Thread Milling Tool Information:

Tools Name: Threading Cutter

Type: Single-Tooth Thread End Mill

Materials: New Ultra-Fine Grain Tungsten Steel Carbide

Thread Standard: Metric

Pitch Type: Coarse / Fine

Flute Numbers: 4 Flute

HRC: 65°

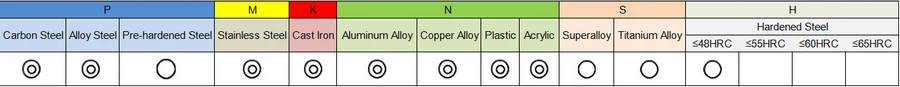

Uncoated Tool Suitable for:

Aluminum, Aluminum Alloys, Copper, Plastics, Magnesium, Zinc, Acrylic, Bakelite, Resin, etc.

Coated Tool Suitable for:

Stainless Steel, Carbon Steel, Alloy Steel, Pre-hardened Steel, Quenched/Hardened Steel, Die Steel, Tool Steel, Titanium Alloy, Cast Iron, Non-ferrous Metals, etc.

Applicable Machinery:

CNC machining centers, precision carving machine, lathes, and other equipment.

2. Carbide Threadmill Features:

Ultra-Fine Grain Tungsten Steel Rod:

Utilizing innovative superfine grain structure as tool substrate,

Delivering exceptional rigidity, wear-resistance, presure tolerance and

Explosion-proof performance for maximized service lifetime.

Nano Coating:

Engineered through high-density, wear-resistant coating technology, to

Provide exceptional durability and enhanced hardness, substantially extending tool life.

Large Chip-Removal Groove Design:

Fully-ground helix angles for expanded chip space,

Preventing buildup and ensuring smooth evacuation to boost cutting efficiency.

Smooth Cutting:

Multiple-flute helical design ensures efficient chip removal, and

Prevents built-up edge, delivering high-precision threads with excellent surface finish and improved productivity.

High Quality:

Precision-ground edges, and large core diameter, increase rigidity and toughness,

Providing sharp and durable performance for extended tool life.

Advantages of Choosing Single-Thread Mills:

Cost-effective, highly versatile, and capable of machining a wide range of threads.

They can cut various pitches and are suitable for both internal and external threads on any straight-shank workpieces,

with no restrictions on thread hardness (left-handed or righ-handed)

Additionally, they enable threading of blind holes, significantly reducing procurement costs.

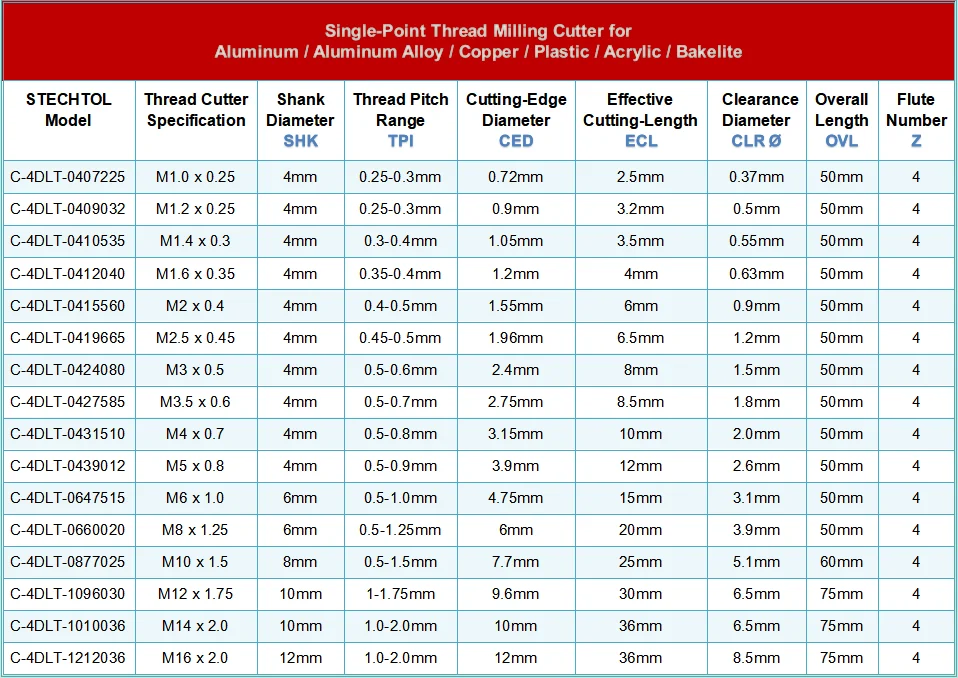

3. Router Bit Specifications:

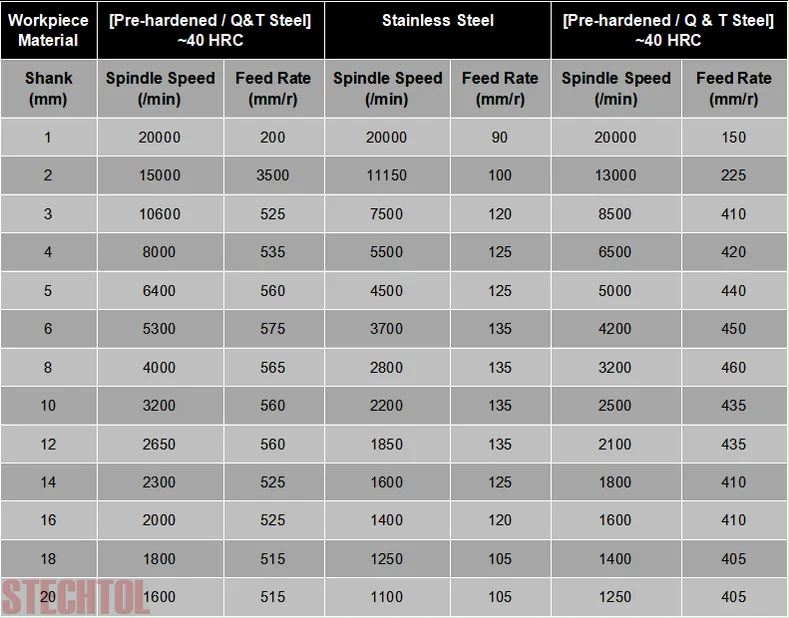

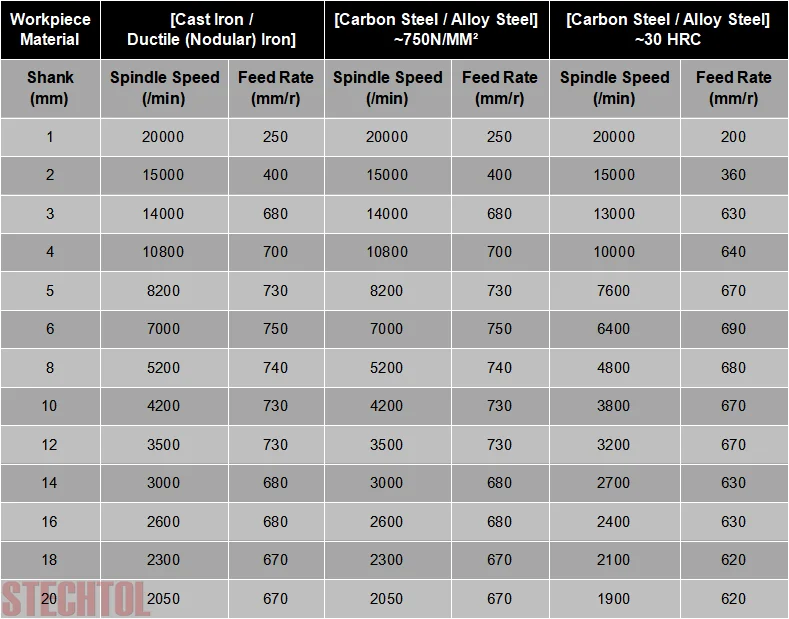

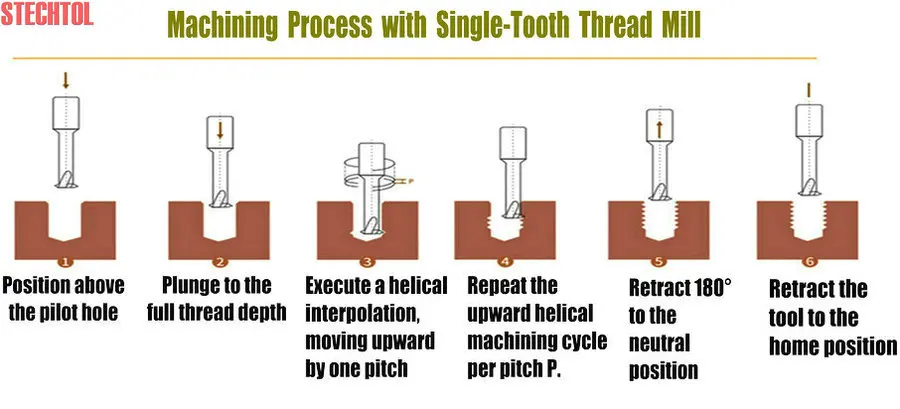

4. CNC Cutter Parameters Setting